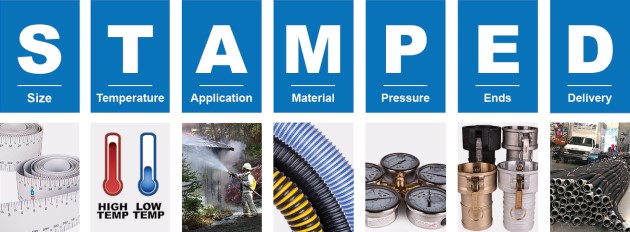

To design a flexible metal hose assembly accurately for a specific application, it is necessary to determine certain parameters initially. In some cases, all the required information may already be provided in a drawing. However, if it is not available, we have devised a helpful mnemonic to remember the necessary details for quoting and fabricating your metal hose assembly. These parameters are organized into the acronym “S.T.A.M.P.E.D.” to aid in memorization.

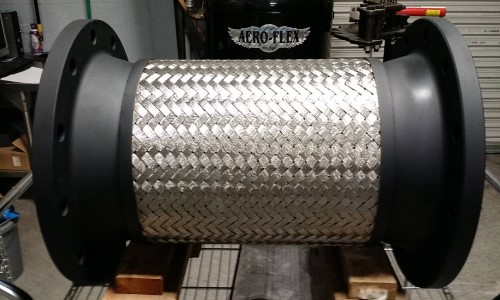

Flexible metal hose and braid are available in a variety of sizes, ranging from 1/4″ to 12″ in diameter. This size range enables adaptability to a variety of applications and system needs. When it comes to pressure ratings, the diameter of the hose is extremely important. Smaller diameter hoses can sustain higher pressures, whereas bigger diameter hoses have lower maximum pressure ratings. The interaction is responsible for the structural characteristics of the hose. Given that smaller diameter hoses have a lower cross-sectional area, the force being applied is dispersed over a smaller surface area. This concentrated force enables the hose to properly manage higher pressures.

Various industries use flexible metal hose assemblies widely because they perform well across an extreme temperature range. For instance, cryogenic applications, such as liquid hydrogen or oxygen transfer hoses, experience temperatures as low as -320°F.

In contrast, using a flexible metal hose assembly allows for achieving significantly higher temperatures compared to a PTFE or rubber hose. The materials they use to manufacture the hose provide this capability. Stainless steel can tolerate both higher and lower temperatures than a PTFE or rubber hose assembly

Flexible metal core and braid are available in a variety of different alloys, with each alloy tailored to a specific application. Typically, the core and braid options include 321ss, 316ss, Alloy 400 (Monel), and Nickel 625. The standard braid alloy is 304 stainless steel, but it can also be substituted with 316ss, Alloy 400, and Nickel 625.

In general, higher temperature applications utilize 321 stainless steel, while corrosive environments benefit from the use of 316L stainless steel. The low carbon content and the addition of molybdenum provide protection against salt and other chemicals used in manufacturing.

The maximum allowable working pressure (MAWP) of a flexible metal hose depends on two factors: the diameter of the hose and the number of layers of wire braid. Additionally, the MAWP can be affected by the temperature of the substance passing through the hose or the surrounding environment.

For example, a flexible metal hose with a 1/4″ inner diameter and 2 layers of braid can withstand a working pressure of 6000 psi. On the other hand, a 12″ flexible metal hose with 2 layers of braid has a working pressure capacity of 325 psi. It is important to consider that exceeding a temperature of 300°F necessitates a reduction in the pressure rating due to the elevated temperature.

Aero-Flex Corp.

3147 Jupiter Park Circle Suite 2

Jupiter, Florida 33458

Hours: M-F 8AM – 5PM

Email: Sales@aero-flex.aero