Did you know that metal hose companies vary in quality? Aero-Flex Corp. distinguishes itself as a premier manufacturer of flexible metal hoses, always prioritizing quality over anything else. Our AS9100D certification for aerospace quality assures that. We realize you have many flexible metal hose manufacturers to choose from, but the assembly method used to fabricate the hose is crucial. Flexible metal hoses usually fail at the welds on the ends, not in the middle. This fact emphasizes the importance of the assembly and welding techniques the fabricator employ’s. Right now, no codes or specifications dictate how to weld metal hoses. So, when you’re choosing a vendor to create your hose assembly, it’s essential to pick one that truly understands flexible metal hoses and knows how to make them correctly. For reliability, trust Aero-Flex as your top flexible metal hose manufacturer!

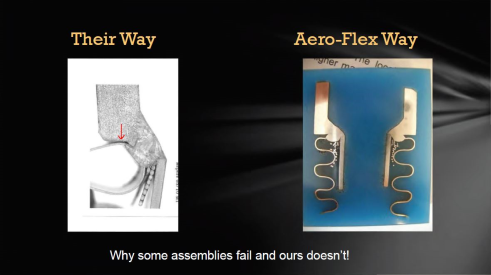

We have a unique flex metal hose construction process in the industry. Most flexible metal hose manufacturers cut the hose from the reel and MIG weld a fitting or flange without any extra end fitting preparation. While this method works for low-pressure, non-critical applications, it often results in incomplete penetration in the hose weld. The hose material is only a few thousandths thick, while the fitting being welded to the hose might be 5–10 times thicker. Applying too much heat to the weld can cause penetration through the hose material’s wall. If you don’t thin the fitting’s wall, you end up with a hinge point that can fail over time. Such flexible metal hoses prioritize low cost over longevity. This distinction sets our flexible metal hose assemblies apart from others in the industry!

Aero-Flex will choose an alloy to construct your flexible metallic hose that is compatible with your specific application. For example, using 316 Stainless Steel is great for minor corrosion or high purity environments. In instances where high corrosion is a factor, nickel or monel is widely used in these applications. For most applications the standard 321ss core with 304ss braid will work fine. Our Flexible Metal Hose Assemblies are extremely abrasion resistant and are widely used in industries where high vibration is a factor. Actually, reducing vibration in your machinery can have a lasting affect on the life span of your machinery. Ask us what alloy is right for your next Flexible Metal Hose application.

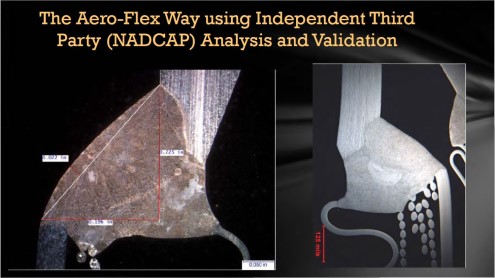

Aero-Flex chooses a different method to fabricate our flexible metal hoses. We have a proprietary method of preparing the hose for welding that is different than 99% of our competitors. Specifically, it involves how we form the hose core and how it relates to the braid and the braid band that ties all 3 together. During prep we perform a process that thins out the wall of the end fitting so that when welded to the hose we get full penetration and that removes the hinge point we referenced earlier. The result is our flexible metal hoses are stronger and more durable for a longer lasting flexible hose assembly over time. This also creates a smooth transition between the hose core and the end fitting. It also removes sharp edges of the core that can interfere with flow inside the flexible metallic hose.

As a top-tier flexible metal hose manufacturer, we prioritize the cleanliness of our flex metal hoses. We clean our flexible metal hose assemblies multiple times: once before preparation and welding, and once more after pressure testing. During the final cleaning, we at Aero-Flex pickle the welds to eliminate impurities (carbon) that surface during the weld’s cool-down. This measure stops the welds from rusting when exposed to environmental moisture. In contrast, our competitors often resort to just soap and water or, at best, mild citric passivation. Such methods don’t effectively remove weld impurities, leading those welds to rust within hours or days when deployed in the field. These distinctions highlight what makes us different from the broader flexible metallic hose industry. We hope you’ll recognize the difference and select Aero-Flex for your upcoming flexible metal hose needs!

There are a lot of different types of hoses on the market today and each of them have their own specific application. Aero-Flex specializes in the fabrication of custom flexible metal hose assemblies for applications where other types of hose materials won’t work. For example, a high temperature or corrosion environment or a really low temperature environment like in cryogenic applications. Here are some examples of applications that require a flexible metal hose.

There are several different threaded end connections that can be used on a metal hose (stainless steel flex hoses). There are also several hydraulic fittings & adapters that can be welded on the hose or can be used to adapt the hose to existing equipment. For the most part materials include carbon steel, 304 stainless steel and 316L stainless steel.

Aero-Flex can also machine a custom threaded end connector to the specific dimensions and alloys you require for your application. Ask us about custom threaded hose connectors and we would be happy to get you a quote.

Typically flange end connections are used on hoses larger than 2″ in diameter. Aero-Flex supplies off the shelf ANSI B16.5 flanges in 150#, 300#, 600#, 900# and 1500# classes. ANSI B16.5 flanges come standard in alloys like carbon steel, 304 stainless steel, 316L stainless steel and 321 stainless steel. When required an Alloy 400 or Nickel 625 flange can also be supplied. Aero-Flex can also machine custom flange connections upon request to your exact drawing specifications and specific alloys. Ask us about your next project that requires flexible metal hoses with custom flange connections and we would be happy to get you a quote.

Aero-Flex provides end connections used on hose and tube assemblies used in Aerospace applications. The aerospace fittings are very similar to the JIC industrial end fittings especially since they are both 37° flares but they do have differences. The most notable difference between these standards are in the threads. For instance, AN fittings use an increased root radius thread (“J” thread) and a tighter tolerance (Class 3) to achieve a 40% increase in fatigue strength and a 10% increase in shear strength. In fact, material requirements can differ greatly. These two fittings function the same, they look the same but are slightly different. But, JIC fittings should not be used for Aerospace applications.

Aero-Flex Corp.

3147 Jupiter Park Circle Suite 2

Jupiter, Florida 33458

Hours: M-F 8AM – 5PM

Email: Sales@aero-flex.aero