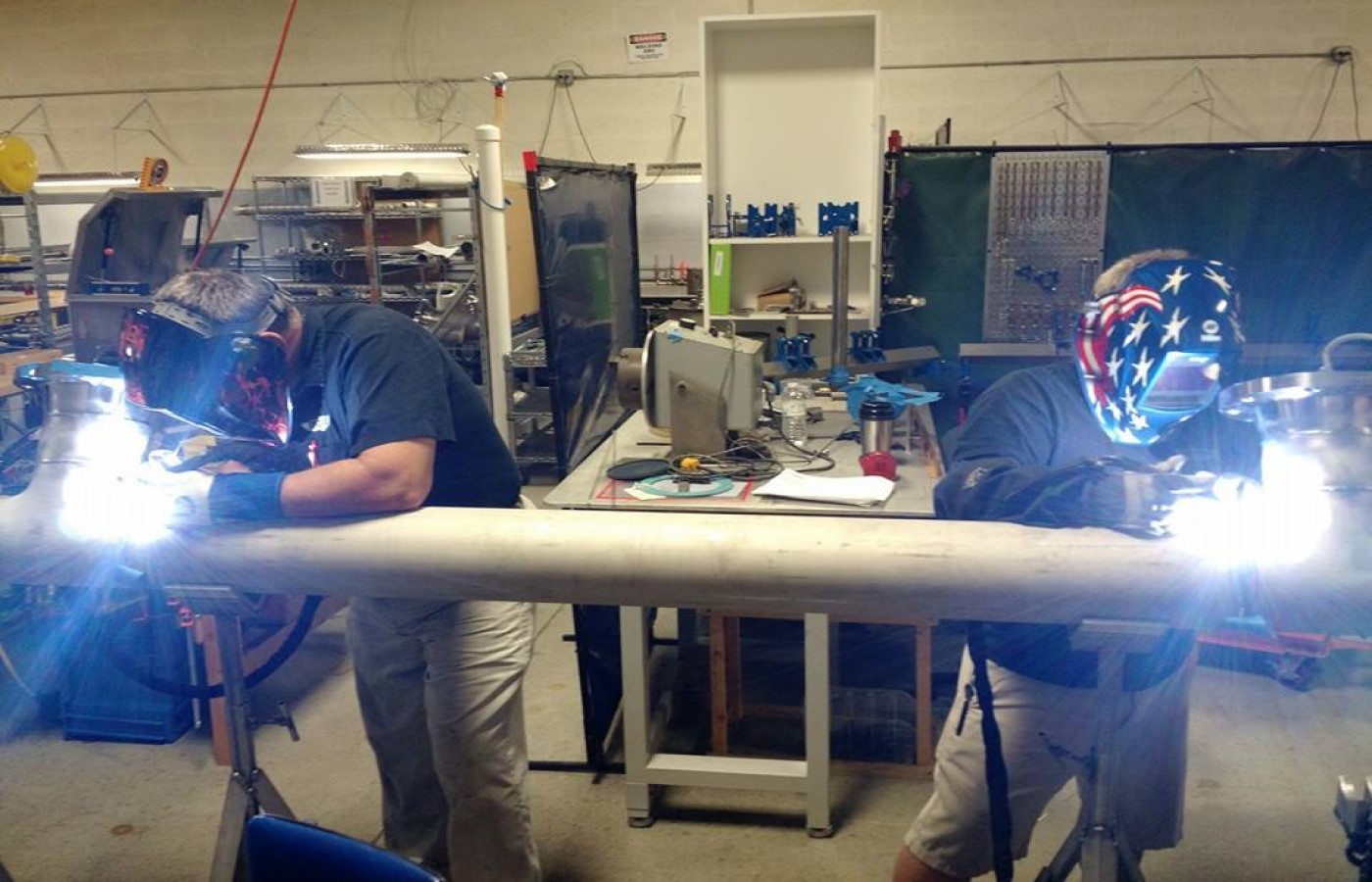

Aero-Flex is a leading global provider of specialty welding services. Our highly skilled welders have the expertise it takes to weld on a full range of materials and specialty welding is a part of our expertise. Aero-Flex is certified to provide specialty welding and industrial welding services for Stainless Steel, Aluminum, Nickel Alloys and other high temperature alloys. We weld to industry standards or to company specific weld specifications. Our in-house procedures result in weld-rejection rates that average less than 1 percent. Also our planning, scheduling and project management ensures a smooth, seamless experience for our customers. For us, it’s about more than just a weld. It’s about ensuring that every weld’s integrity equates to reliable and safe operations.

Aero-Flex puts safety, efficiency and quality into every weld from the beginning. This helps to keep your projects on time and on budget. Once your part arrives, we check them in using our customer supplied material database. This allows us to keep track of everything you provided us. The lot number also helps us trace your product as it moves through our shop. The shop traveler is created by using your provided drawing or instructions. Eventually the traveler gets released to the welder to start production.

All specialty welding services that Aero-Flex performs require a weld procedure. We can use an existing procedure if it meets all of the requirements. But sometimes we must create a procedure before welding on your product. Don’t worry this happens from time to time. We are able to create the weld samples and then perform the required tests to qualify the weld. The specification determines how we perform these tests and qualifications for your specialty welding project.

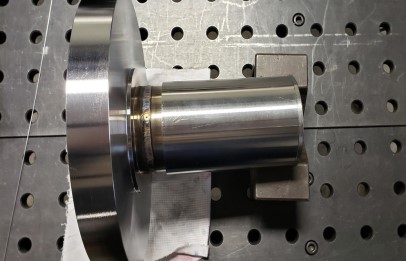

When performing a specialty weld it’s important to consider the metallurgy of the material. You must also understand the type of weld you are performing. Aero-Flex requires a qualification process for all specialty welding services done in our shop. We confirm everything is dialed in before performing the actual weld on your product. During weld testing we learn a lot about how the metal behaves. We will watch how it behaves during heating and cooling and observe any movement that may occur. Additionally, to qualify the integrity of the weld this may include NDT, tensile and bend tests .

All of our welders are certified to D17.1 for Aerospace welding and ASME codes for Industrial welding. This allows any one of our certified welders to perform the specialty welding on your product. Once your product is welded, we take it to pressure testing (if required) and then final cleaning. Aero-Flex removes impurities from the welding process by using a strong acid. This prevents any rust from forming on the weld. This process removes carbon from deep within the weld during the process. You’ll find that most weld shops only go as far as a mild de-greaser or citric passivation and DO NOT perform pickling of the welds. This won’t work and once installed you will see rust form immediately on the weld once it is exposed to moisture in the air or environment.

Full traceability of materials is sometimes required by our customers. Aero-Flex will supply material test reports for any materials used on your project. We also include a certificate of conformance that certifies Aero-Flex performed the specialty welding services to the exact specifications on your purchase order. With over 75 years of experience we work closely with our customers to ensure your specialty welding projects are delivered on-time with superior quality. We have the resources, experience and expert knowledge it takes to deliver our specialty welding projects of all scopes and specifications on-time. We also provide Aerospace welding and Industrial Welding services to cover all of your needs. Our project managers are ready to help you with any project that you may have.

Aero-Flex Corp.

3147 Jupiter Park Circle Suite 2

Jupiter, Florida 33458

Hours: M-F 8AM – 5PM

Email: Sales@aero-flex.aero