Vacuum Jacketed Flex Hoses

As global industries move relentlessly toward the cutting-edge of scientific and technological innovation, the role of cryogenic liquid transfer—including liquid hydrogen, liquid helium, and liquid oxygen—becomes ever more vital. Particularly within sectors such as aerospace, this field has gained paramount importance. With cryogenic experience exceeding 30 years in the development and fabrication of cryogenic vacuum-jacketed products, Aero-Flex Corp. sets an industry benchmark by furnishing highly proficient and trustworthy solutions for the conveyance of cryogenic liquids.

Aero-Flex Corp. vacuum jacketed flex hoses are fabricated to the highest quality outlasting our competitors in durability and the integrity of the vacuum. This is key to the transfer of cryogenic liquids as cold as liquid hydrogen and liquid helium. Trust in Aero-Flex Corp. to provide the best solutions for your cryogenic vacuum jacketed hose or piping requirements.

Understanding Vacuum-Jacketed Hoses

Aero-Flex Corp. excels in the manufacturing of vacuum-jacketed hoses and piping, a specialized innovation that revolutionizes the transportation of cryogenic liquids. These high-performance solutions are designed to minimize heat transfer and maintain the ultra-low temperatures required for the safe and efficient transfer of liquefied gases. The unique construction of vacuum-jacketed flex hoses consists of an inner and outer stainless steel hose or pipe, with the space between them evacuated to create a vacuum layer. This vacuum layer acts as a thermal insulator, significantly reducing heat transfer by conduction and convection.

Our Unique Construction

The unique construction of vacuum-jacketed flex hoses embodies innovation and functionality. It consists of:

Inner Stainless Steel Hose/Pipe: This inner conduit is the primary carrier of the cryogenic liquid. Made of specialized stainless steel, it is designed to withstand extreme temperatures without losing integrity or performance.

Outer Stainless Steel Hose/Pipe: Surrounding the inner pipe, the outer stainless steel pipe serves as a protective layer. This construction adds durability and resistance against environmental factors, such as temperature fluctuations, physical damage, or corrosive conditions.

Vacuum Layer: Between the inner and outer pipes is a space that has been carefully evacuated to create a vacuum layer. This absence of air acts as a thermal insulator, significantly reducing heat transfer by conduction and convection.

Additional Insulating Materials: In some configurations, additional layers of insulating material may be used to further enhance the insulating properties of the vacuum jacket from UV. This can include materials known for their high thermal resistance like aluminized mylar, which complements the vacuum layer by reflecting the UV that may enter the hose so that it doesn’t affect the the temperature of the the cryogenic liquid inside. .

Thermal Insulation: An In-Depth Look

The vacuum layer’s function as a thermal insulator is a core aspect of the technology. By creating a vacuum, the molecules responsible for transmitting heat through conduction and convection are virtually eliminated. This results in an environment where thermal energy has difficulty moving from the warm exterior to the cold interior, thus preserving the cryogenic liquid’s temperature. As an added layer of protection, aluminized Mylar is wrapped around the inner hose at a specific amount of wraps. This will help scatter the UV that enters the hoses outer layer. This additional layer of protection along with the vacuum assures the ectremely cold cryogenic liquid flowing through the inner hose is not affected in any way.

This sophisticated approach to insulation provides significant advantages over traditional methods, offering a higher level of efficiency in maintaining temperature, reduced energy consumption, and an extended lifespan for the equipment.

Applications and Impact

Aero-Flex Corp.’s vacuum-jacketed hoses and piping are not just technological marvels; they have tangible impacts on industries dealing with cryogenic materials. Their ability to minimize heat transfer ensures that more of the transported liquid reaches its destination without transitioning into gas, reducing waste, and enhancing efficiency. The robust construction also ensures a level of safety and reliability that is essential in fields where precision and performance are paramount.

Aero-Flex Corp.’s innovation in vacuum-jacketed flex hoses and piping is a milestone in the cryogenic industry. It demonstrates a successful marriage of technology, materials science, and engineering that leads to optimized performance, safety, and economic benefits across various applications. It is a testament to the company’s commitment to advancing the frontiers of cryogenic liquid transfer technology.

The Superiority of Aero-Flex Corp.'s Vacuum-Jacketed Approach

Augmented Thermal Efficiency: Our vacuum-jacketed hose and piping design powerfully curtails heat intrusion from the ambient surroundings, minimizing vaporization and the cryogenic liquid’s stability at its intended temperature throughout transfer. This translates to tangible cost savings, bolstered operational safety, and heightened overall functionality.

Unwavering Safety Commitment: When it comes to handling cryogenic liquids, safety is non-negotiable. Aero-Flex Corp.’s products are rigorously engineered to our AS9100D-certified quality program for aerospace compliance, meeting the most demanding industry criteria. This certification illustrates our steadfast commitment to quality and safety, furnishing both our clients and end-users with confidence.

Tailor-Made Solutions: Acknowledging the distinctiveness of each cryogenic application, we render specialized solutions aligning with explicit project demands. Our adept engineering team collaborates intimately with clients to fathom their requirements, producing custom-fitted vacuum-jacketed hoses and piping to guarantee flawless integration and peak performance.

Diminished Boil-off and Waste: The outstanding thermal insulation of our vacuum-jacketed products curtails the cryogenic liquid’s boil-off rate during transfer. This conserves resources by minimizing product loss and waste, an essential consideration in critical applications and cost-conscious fields.

Broad Applications of Aero-Flex Corp.'s Vacuum-Jacketed Transfer Solutions

Aero-Flex Corp.’s products serve diverse industries, such as:

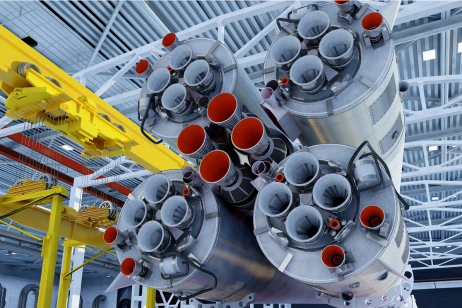

Aerospace: AS9100D-certified hoses are crafted to meet the rigorous demands of aerospace, facilitating proficient cryogenic liquid transfer in areas like space exploration, satellite propulsion, and rocket engine validation.

Medical and Research: With a central role in medicine and research, Aero-Flex Corp.’s vacuum-jacketed hoses serve in environments like labs, healthcare institutions, and research hubs for functions such as MRI machines, cryopreservation, and cryosurgical procedures.

Energy and Power: The energy sector leverages cryogenic liquids for LNG storage and transit. Our hoses aid in safe and efficient LNG conveyance, advancing clean and dependable energy resolutions.

Aero-Flex Corp. emerges as a paragon in the sphere of cryogenic liquid transfer, harnessing 30 years of mastery to develop vacuum-jacketed hoses and piping that set new standards in efficiency, safety, and execution. Our unswerving dedication to top-tier engineering, buttressed by our AS9100D certification, ensures that clients reap world-leading solutions for their distinct cryogenic liquid transfer needs.

Aero-Flex Corp.’s vacuum-jacketed offerings symbolize a future in cryogenic liquid transfer that is both bright and secure. Our allegiance to excellence persists unshaken as we persistently innovate and lead in solutions that redefine the conceivable boundaries within the cryogenics field.

Learn More About How Aero-Flex Corp Can Help Your Company

Learn How To Order A Flexible Metal Hose Assembly From Aero-Flex Corp. Here

Learn More About When Flexible Metal Hose Should Be Used Here

Learn More About ASME Piping Assemblies Here

Learn More About Cryogenic Transfer Hoses Here

Learn More About High Temperature Air And Steam Hoses Aero-Flex Corp. Can Provide Here