Understanding the use of Flexible Metal Hoses in various industries.

At Aero-Flex Corp, we take pride in providing our customers with high-quality flexible metal solutions for a wide range of applications. Flexible metal hoses offer unique advantages, making them an ideal choice for various industries and environments. In this comprehensive article, we will delve into the reasons why and when to use flexible metal, exploring its features, benefits, and applications.

Introduction to Flexible Metal Hoses

Flexible metal refers to a type of hose or tubing constructed using a series of annular, interlocked or helically-wound metal strips. This design enables the hose to withstand high pressure, extreme temperatures, and challenging environmental conditions while maintaining flexibility and durability. The flexibility of these hoses is achieved by the use of corrugations, which provide expansion and contraction capabilities.

The Advantages of Flexible Metal Hoses

High Temperature Resistance: Flexible metal hoses are engineered to withstand extreme temperatures, making them suitable for applications that involve hot fluids, steam, or high-temperature gases. The ability to withstand heat without compromising structural integrity is crucial in industries such as aerospace, oil and gas, and manufacturing.

Pressure Resistance: Another key advantage of flexible metal hoses is their ability to handle high-pressure environments. The interlocked or helically-wound metal strips provide strength and stability, allowing the hose to resist the internal pressure exerted by fluids or gases. This makes flexible metal hoses ideal for applications in hydraulic systems, industrial processes, and pneumatic equipment.

Corrosion Resistance: Flexible metal hoses are often made from stainless steel or other corrosion-resistant materials, which enables them to withstand the effects of corrosive substances. This corrosion resistance makes them suitable for applications involving chemicals, acids, or saltwater environments, where conventional hoses may fail prematurely.

Flexibility and Durability: The inherent flexibility of flexible metal hoses allows for easy installation, even in tight spaces or areas with complex routing requirements. Their durability ensures a long service life, reducing the need for frequent replacements and minimizing maintenance costs.

Vibration Absorption: Flexible metal hoses have excellent vibration absorption properties, reducing the transmission of vibrations from machinery or equipment. This feature is particularly beneficial in industries such as power generation, where excessive vibrations can lead to equipment damage or performance issues.

Where Are Flexible Metal Hoses Used In Industry?

1. Industrial and Manufacturing: Flexible metal hoses find widespread use in industrial settings, including manufacturing plants, refineries, and power generation facilities. They are used for conveying various fluids and gases, such as oil, water, steam, and chemicals. Common applications include process piping, cooling systems, and exhaust ducts.

2. Aerospace and Aviation: The aerospace industry relies on flexible metal hoses for critical applications, such as aircraft fuel systems, hydraulic lines, and pneumatic systems. The hoses’ ability to withstand high temperatures, pressure differentials, and vibrations is crucial in ensuring the safety and reliability of aerospace operations.

3. Oil and Gas: In the oil and gas industry, flexible metal hoses play a vital role in offshore drilling, oil refineries, and petrochemical plants. They are used for transferring oil, gas, and other fluids between different components, providing flexibility in a dynamic and challenging environment.

4. Medical and Pharmaceutical: Flexible metal hoses are utilized in medical and pharmaceutical applications that require precise fluid transfer, such as in laboratory equipment, diagnostic instruments, and pharmaceutical manufacturing processes. The hoses’ resistance to corrosion and high temperatures ensures compliance with stringent quality and safety standards.

5. Automotive: Flexible metal hoses are found in various automotive systems, including exhaust systems, fuel lines, and braking systems. The ability to handle high temperatures and resist vibrations makes them a reliable choice for ensuring optimal performance and safety in vehicles.

Below we will expand on each of the above uses of flexible metal hoses and get specific on how they are used in different industries.

Enhancing Industrial Processes with Flexible Metal Hoses

In the realm of industrial and manufacturing operations, flexible metal hoses prove to be invaluable tools. Their ability to effectively convey different fluids and gases makes them essential in a multitude of applications. Let’s delve deeper into some key industrial uses:

1. Process Piping: Flexible metal hoses are widely employed in process piping systems, facilitating the transportation of fluids and gases. Whether it’s the movement of oil, water, steam, chemicals, or even abrasive materials, flexible metal hoses provide a reliable and durable solution, ensuring efficient operations in manufacturing plants, refineries, and power generation facilities.

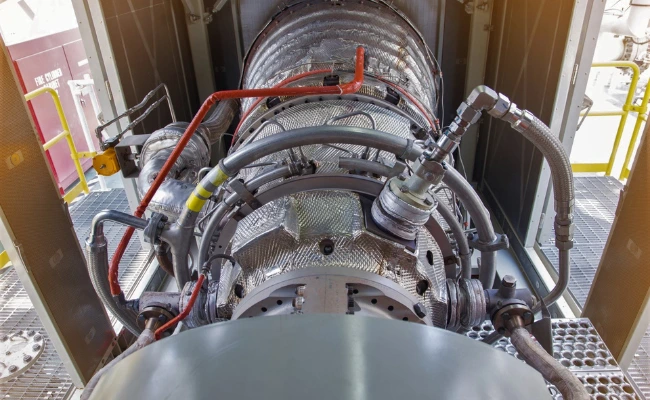

2. Gas Turbines: Flexible metal hoses play a crucial role in the operation of gas turbines and power plants. These hoses are designed to withstand high temperatures, pressures, and vibrations, making them ideal for transferring various fluids and gases within the systems. They provide flexibility, allowing for easy installation and maintenance, as they can be bent and positioned in tight spaces. The use of flexible metal hoses ensures efficient flow of fuel, oil, coolant, and other media, enabling smooth operation of gas turbines and power plants. They also contribute to the overall safety of the systems by minimizing the risk of leaks and failures. With their ability to handle extreme conditions and offer adaptability, flexible metal hoses are indispensable components in the reliable functioning of gas turbines and power plants.

3. Chemical: The chemical sector encompasses a wide range of activities, spanning from the production of industrial gases to the creation of cosmetics and paint. What makes metal a valuable material in the chemical industry? Corrugated metal hoses can be crafted using different alloys to offer optimal protection against corrosion in their designated applications. An example of this is seen in the chlorine transfer industry, where metal hoses have been purposefully engineered with a high-nickel alloy to counteract corrosion and enhance the safety of workers.

Enabling Optimal Performance in Automotive Systems

Flexible metal hoses play a significant role in the automotive industry, contributing to the performance, safety, and reliability of various systems:

1. Exhaust Systems: Automotive exhaust systems face high temperatures and undergo significant vibrations. Flexible metal hoses, designed to withstand these conditions, are utilized in exhaust systems to effectively transport exhaust gases. Their durability ensures optimal performance, while their flexibility allows for easy installation and routing.

2. Fuel Lines: Fuel lines in vehicles need to safely transport fuel from the tank to the engine. Flexible metal hoses, with their resistance to heat and vibration, provide a reliable conduit for fuel flow. These hoses contribute to the efficient operation of the fuel system, promoting the overall performance and longevity of the vehicle.

3. Braking Systems: The braking system is a critical safety component in automobiles. Flexible metal hoses, specifically designed for brake applications, are used to transport brake fluid from the master cylinder to the brake calipers or wheel cylinders. Their ability to handle high pressures and resist corrosion ensures optimal braking performance and safety.

Reliable Solutions for the Oil and Gas Industry

The oil and gas industry operates in demanding environments where reliability and safety are paramount. Flexible metal hoses provide key advantages in various oil and gas applications:

1. Offshore Drilling: Offshore drilling operations require equipment that can withstand harsh marine conditions. Flexible metal hoses are utilized for transferring oil, gas, and other fluids between different components in offshore drilling rigs. Their flexibility and corrosion resistance make them suitable for withstanding the dynamic nature of these operations.

2. Oil Refineries: Within oil refineries, numerous processes involve the handling and transportation of corrosive substances. Flexible metal hoses, constructed from corrosion-resistant materials, provide the necessary durability and resistance to chemical corrosion. They ensure the safe and efficient movement of fluids, contributing to the smooth operation of refining processes.

3. Petrochemical Plants: Petrochemical plants deal with a wide array of chemicals, often in challenging operating conditions. Flexible metal hoses, with their resistance to corrosion and ability to withstand high temperatures, are critical for transferring chemicals safely and reliably. These hoses play a vital role in maintaining the integrity and efficiency of petrochemical processes.

Innovations in the Aerospace and Aviation Sectors

The aerospace and aviation industries demand the highest standards of safety, reliability, and performance. Flexible metal hoses play a critical role in meeting these requirements in several key applications:

1. Aircraft Fuel Systems: The safe and efficient transportation of fuel is of paramount importance in aircraft operations. Flexible metal hoses are utilized in fuel systems, ensuring the reliable flow of fuel between various components. With their ability to withstand high temperatures, pressure differentials, and vibrations, these hoses contribute to the overall safety and performance of aircraft.

2. Hydraulic Lines: Hydraulic systems are essential for operating flight controls, landing gears, and various aircraft components. Flexible metal hoses, with their strength, flexibility, and resistance to corrosion, are vital for hydraulic lines. They enable the precise transfer of hydraulic fluid, ensuring optimal performance and safety during flight.

3. Pneumatic Systems: Pneumatic systems rely on compressed air to power critical aircraft functions. Flexible metal hoses find applications in pneumatic systems, allowing the efficient and reliable transmission of compressed air. Their ability to handle high pressures and extreme temperatures is vital for maintaining the integrity of these systems.

Meeting Stringent Requirements in the Medical and Pharmaceutical Fields

The medical and pharmaceutical industries demand precise fluid transfer systems that adhere to rigorous quality and safety standards. Flexible metal hoses find applications in these sectors, offering several key advantages:

1. Laboratory Equipment: In laboratory settings, flexible metal hoses are used in various equipment, such as analytical instruments, chromatography systems, and sample-handling devices. Their resistance to corrosion and high temperatures ensures the accuracy and integrity of fluid transfer, supporting precise experimental procedures and reliable results.

2. Diagnostic Instruments: Medical diagnostic instruments often require the controlled movement of fluids and gases. Flexible metal hoses play a vital role in these instruments, providing a reliable conduit for transferring samples, reagents, and calibration fluids. The hoses’ durability and flexibility contribute to accurate diagnostic procedures and efficient operations.

3. Pharmaceutical Manufacturing: Within pharmaceutical manufacturing processes, maintaining aseptic conditions and ensuring product purity are critical. Flexible metal hoses are used in various stages of production, facilitating the transfer of ingredients, solvents, and intermediates. The hoses’ resistance to corrosion and high temperatures supports the adherence to strict quality standards, promoting the safe and efficient manufacturing of pharmaceutical products.

Conclusion

Flexible metal hoses offer a multitude of benefits, making them indispensable in numerous industries and applications. Their unique combination of high temperature and pressure resistance, corrosion resistance, flexibility, durability, and vibration absorption sets them apart from conventional hose options. Whether in industrial settings, aerospace, oil and gas, medical, or automotive applications, flexible metal hoses provide reliable performance and contribute to enhanced operational efficiency and safety.

At Aero-Flex Corp, we specialize in providing top-quality flexible metal hoses tailored to your specific requirements. With our extensive experience and commitment to excellence, we are confident in our ability to deliver the most reliable and durable solutions for your needs. Contact us today to discuss your application and benefit from our expertise in flexible metal technology.